Lin Yu Chieh and Marielena Papandreou

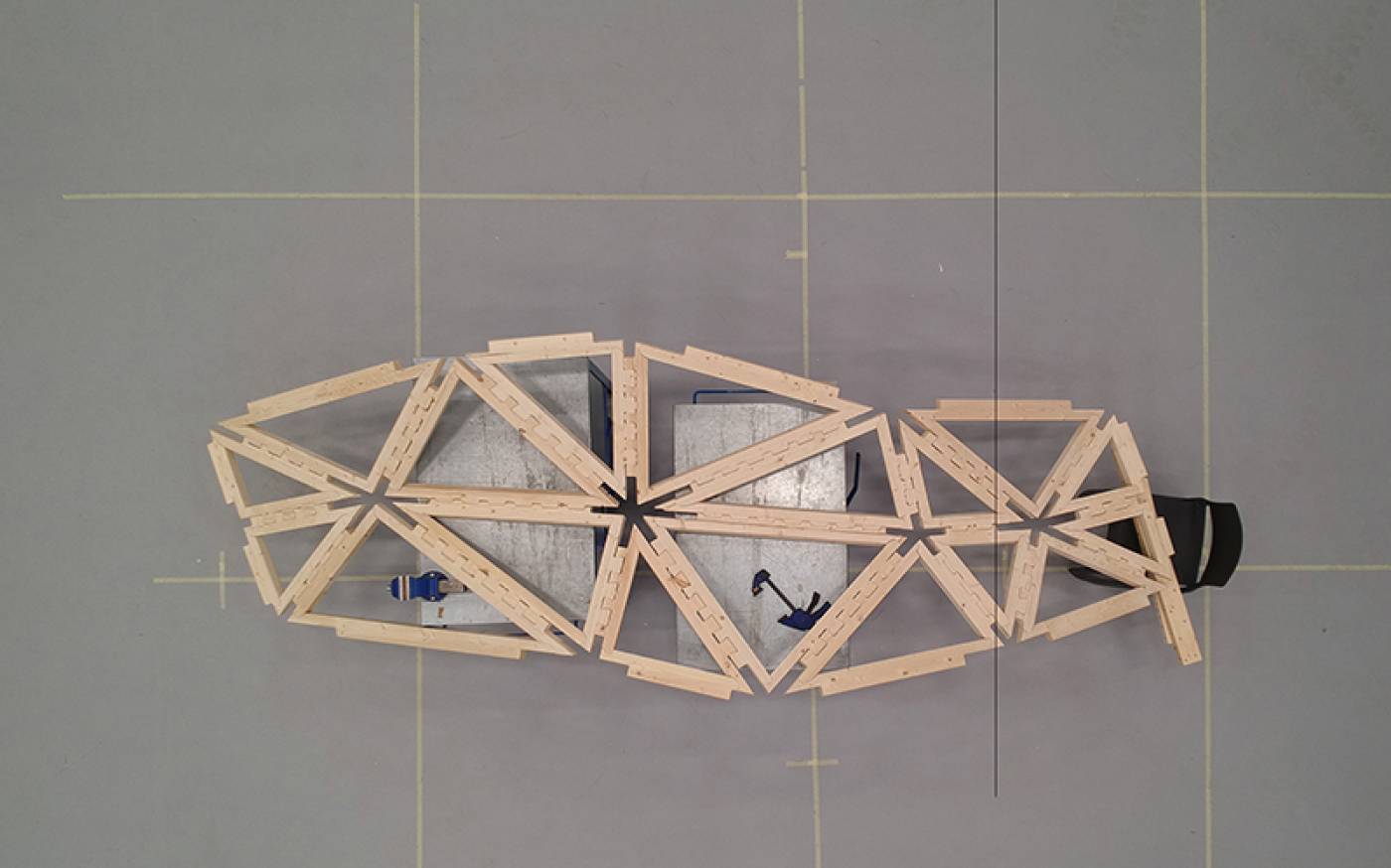

The aim of this project is to create a process from the design to the production of timber elements in a continuous digital workflow.

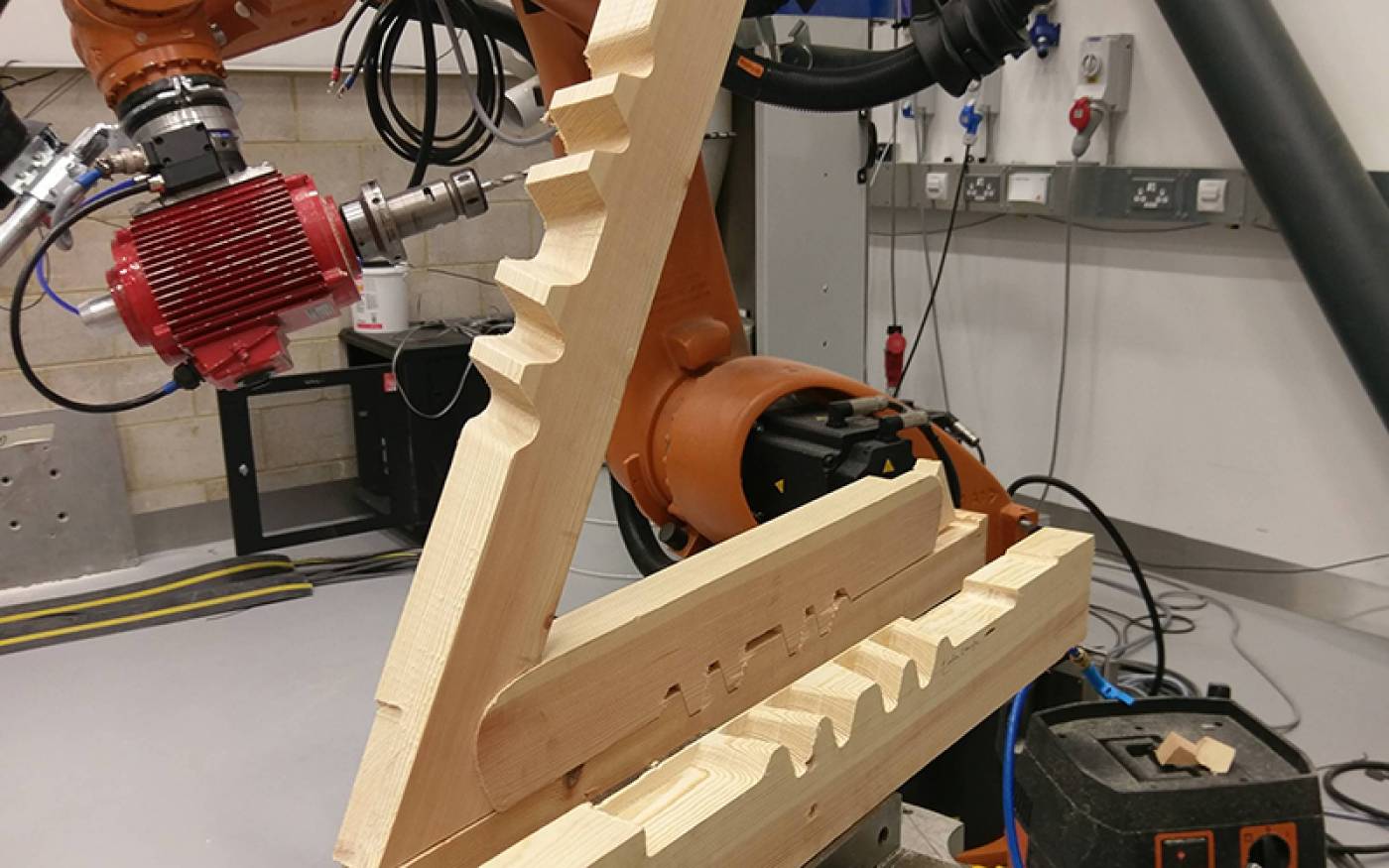

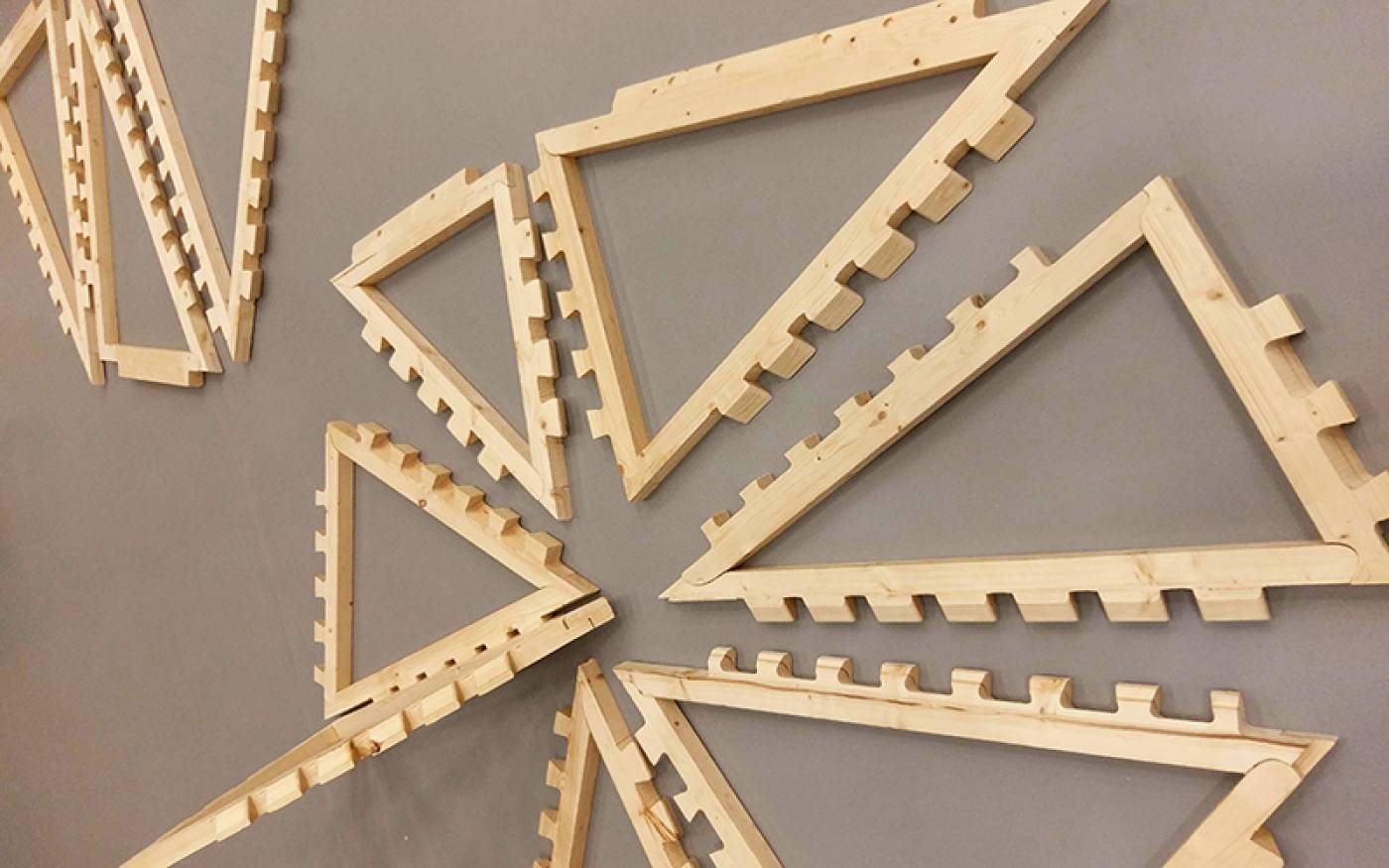

A triangulated structure is chosen as a demonstrator to prove this process while an industrial robot is used as the medium to execute the fabrication operations. For the connection of the beams a set of innovative timber joints was developed.

Robot control strategies become a primordial part of the synthesis as they influence the shapes of the connections from the beginning of the design process. Advanced computational tools are used in conjunction with an industrial robot to carry out a combination of subtractive robotic tasks.

The process from design to production is controlled through a single software platform that contains all geometric, structural and fabrication properties and constraints. Custom hardware is designed to facilitate the machining of the timber components. A tracking system is tested to minimise the time of production and maximise precision by updating data with regard to material deviations.

Close

Close