Why do we need a Quality Management System (QMS)?

- We must meet the regulatory requirements for all products that we sell.

- We need to meet customer expectations by producing high quality and consistent products that are SAFE.

- A QMS enables us to demonstrate through evidence that we are producing products that meet the required reliability and test criteria.

- We are using controlled manufacturing methods.

- We take action if there is a problem (through a managing non-conformity procedure).

- We consider risk throughout the design and development process etc.

- We monitor device performance.

- We audit what we are producing to continuously improve our ways of working/device.

ISO 13485:2016

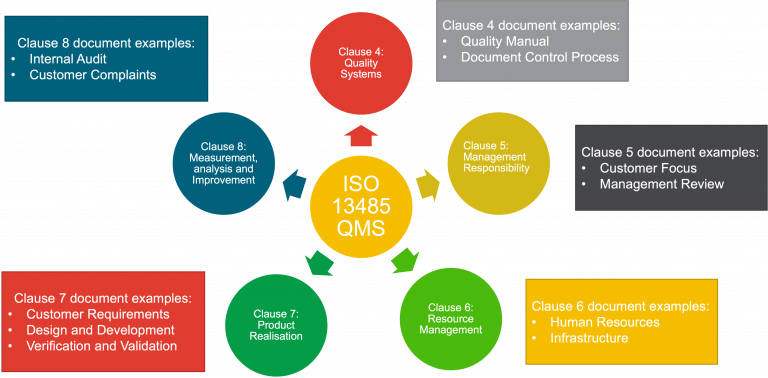

For medical devices the QMS ISO standard that is often used is ISO 13485. This international standard specifies the requirements for a QMS where an organization needs to demonstrate its ability to provide medical devices and related services. It is split into different clauses:

- Clauses 0-3 are:

- Introduction to a QMS

- Scope

- Normative references

- Terms and definitions

- Clause 4 relates to the Quality Management System

- Clause 5 relates to Management Responsibility

- Clause 6 relates to Resource Management

- Clause 7 is Product Realisation

- Clause 8 is Measurement, Analysis and Improvement

- ISO 13485-QMS requirements example documents

- A strategy for regulatory compliance and procedures for modifications to the device

- Identification of and addressing applicable General Safety and Performance Requirements (GSPR's)

- Responsibility of management

- Resource management, including selection and control of suppliers and sub-contractors

- Risk management

- Clinical evaluation including Post Market Clinical Follow-up

- Product realisation, including planning, design, development, production and service provision

- UDI assignments and labelling

- Setting-up, implementation and maintenance of a post-market surveillance system

- Communication with competent authorities, notified bodies, other stakeholders

- Processes for reporting of serious incidents

- Management of corrective and preventative actions and verification of their effectiveness

- Processes for monitoring and measurement of output, data analysis and product improvement

A QMS is usualy structured like the diagram below:

Top Level Policies

- These are a series of higher levels documents that cover all areas of the QMS.

- They detail how we ensure compliance to regulations, legislation and standards.

- All documents within the QMS should comply to top level policies.

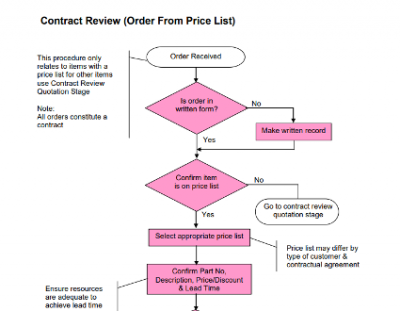

Processes

- These are documents which are instructions on how to conduct a particular action. This can include manufacture instructions or methods of how to conduct an internal audit or management review.

- We must carry out actions as they are described in these documents.

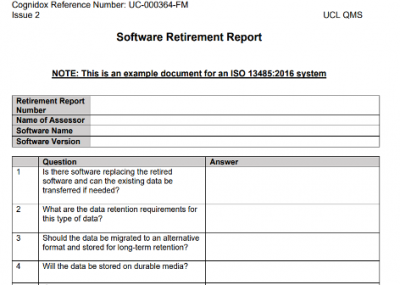

Forms/Records

These are records that form the actual evidence that we have followed a process/policy in a compliant way. They also provide traceability.

Types of Records

Examples include:

- In the development stage, the data generated shows that the device is fit for purpose and has met the regulations for use.

- During manufacturing, we note how we tested the manufactured product.

- To evaluate our suppliers a record is taken of approved suppliers.

- We also have compliant handling records to document investigations.

Document control

Is a key requirement in a QMS. All Quality Systems documents must be controlled as part of the Quality Management System.

All controlled documents have:

- Unique document numbers

- Revision numbers

- Numbered pages

All individuals working within a QMS have te responsibility to ensure good document control is maintained for traceability purposes. You can find out more about document control here.

Audits

- Audits are required to demonstrate compliance as well as continuous improvement of the QMS and device.

- Internal audits will be carried out on a regular basis as part of ISO 13485:2016.

- External audits are carried out by external bodies such as The British Standards Institute (BSI) to ensure that compliance to ISO 13485:2016 is maintained.

- You should expect audits to be a regular occurrence when working/managing a QMS.

Operating a QMS

- Keep it simple and start small

- Start early to get people used to 'processes'

- Only introduce processes that are needed - you need to maintain and use them

- Ensure management reviews cover QMS requirements

Close

Close