To allow the highest quality of workmanship, specific equipment for bending and cropping the leads of surface mount IC packages has been procured.

To allow the highest quality of workmanship, specific equipment for bending and cropping the leads of surface mount IC packages has been procured. Other specialist equipment includes Metcal soldering irons, with very good tip temperature stability, a de-golding pot, solder bath and a stereo microscope with a 360 degree rotating turret that allows solder joints to be inspected from every viewing angle, without moving the assembly.

Vision Engineering TS4 Inspection System

IBL SLC504 Vapour Phase reflow oven (front)

IBL SLC504 Vapour Phase reflow oven (back)

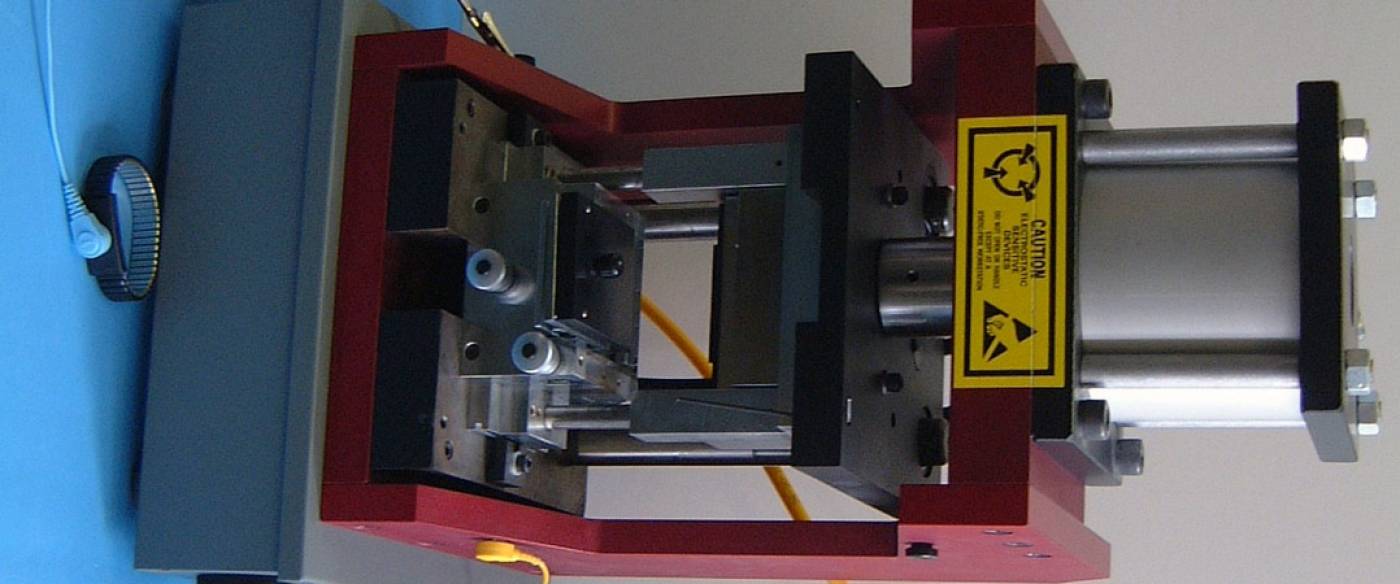

Elite Engineering Pneumatic flat pack lead bender

Essemtec FLX2010V pick and place machine

Essemtec SP003 Semi-automatic Stencil printer

Essemtec FLX2010V pick and place machine

1. COGNEX Vision system

2. Place components from 0201 to 50mm square

3. Laser and vision centering for accurate placement down to 0.3mm 12thou pitch

4. Recognition of PCB reference marks to align the PCB

5. Max Board size 450mm x 350mm

IBL SLC504 Vapour Phase reflow oven

1. IR pre heat for high mass PCBs

2. Rapid cooling system to shorten time from soldering to solidification of the solder joint

3. PC control of temperature profile

4. Four thermocouples to monitor different temperatures around the PCB

5. Max Board size 540mm x 340mm

Essemtec SP003 Semi-automatic Stencil printer

Elite Engineering Pneumatic flat pack lead bender

Vision Engineering TS4 Inspection System

.

Close

Close